-

Manufacturer, Supplier, Exporter ofComputer Servo Controlled Ball Screw Driven UTM

Manufacturer, Supplier, Exporter ofComputer Servo Controlled Ball Screw Driven UTM -

Manufacturer, Supplier, Exporter ofFront Open Hydraulic Grips Universal Testing Machines

Manufacturer, Supplier, Exporter ofFront Open Hydraulic Grips Universal Testing Machines -

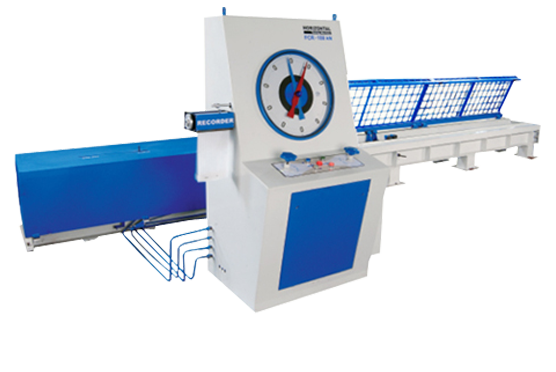

Manufacturer, Supplier, Exporter ofAnalogue Horizontal Chain & Rope Testing Machines

Manufacturer, Supplier, Exporter ofAnalogue Horizontal Chain & Rope Testing Machines -

Manufacturer, Supplier, Exporter ofDeep Throat Brinell Hardness Testing Machines

Manufacturer, Supplier, Exporter ofDeep Throat Brinell Hardness Testing Machines -

Manufacturer, Supplier, Exporter ofDynamic Hardness Testers

Manufacturer, Supplier, Exporter ofDynamic Hardness Testers -

Manufacturer, Supplier, Exporter ofASTM Impact Testing Machines

Manufacturer, Supplier, Exporter ofASTM Impact Testing Machines -

Manufacturer, Supplier, Exporter ofStandard Rockwell Hardness Testing Machines

Manufacturer, Supplier, Exporter ofStandard Rockwell Hardness Testing Machines -

Manufacturer, Supplier, Exporter ofHorizontal Type DSP Based Dynamic Balancing Machines

Manufacturer, Supplier, Exporter ofHorizontal Type DSP Based Dynamic Balancing Machines -

Manufacturer, Supplier, Exporter ofVertical Type Dynamic Balancing Machines

Manufacturer, Supplier, Exporter ofVertical Type Dynamic Balancing Machines -

Manufacturer, Supplier, Exporter ofVickers Cum Brinell Hardness Testing Machines

Manufacturer, Supplier, Exporter ofVickers Cum Brinell Hardness Testing Machines -

Manufacturer, Supplier, Exporter ofDigital Rockwell Hardness Testers

Manufacturer, Supplier, Exporter ofDigital Rockwell Hardness Testers

About Fine Group's

We are Manufacturer, Supplier, Exporter & Services of Material Testing Machines, Universal Testing Machines, Spring Testing Machines, Tensile Testing Machines, Compression Testing Machines...

Fine Group Products

Welcome to FINE GROUP the group of companies in Miraj (Maharashtra State - INDIA) are one of the leading manufacturer of Material Testing Machines. All these years the group is involved for excellence in quality of standards of products and now we can proclaim with pride that we have achieved it. Our products have always maintained the quality standards. We have a world wide clients including companies from America, Africa, Europe, Asia & Gulf. We also have many clients in India.

Over years, FINE GROUP has imbibed plentiful of resources to enhance manufacturing abilities

Read MoreSufficiently large land area as well as factory and office buildings. Handling facility upto 10 Tons

Read MoreHighly qualified Engineers, Workers and the staff trained in their respective fields and having long experience.

Read More